Chopped Strand Mats are nnon-woven fabrics consisting of randomly distributed chopped strands held together with a powder or emulsion binder. Chopped Strand Mat is compatible with unsaturated polyester, vinyle ester, epoxy and phenolic resins. The products are most widely used in hand lay-up process and can also be used in filament winding, Compression molding and continuous laminating processes. The typical end-use applications include various panels, boats, FRP roofing sheet, Automotive parts, bathroom equipment and cooling towers.

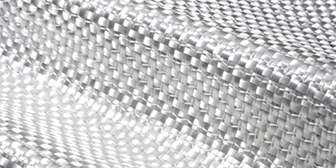

Woven Rovings are bi-directional fabric made by weaving direct rovings. Woven Roving are compatible with many resin systems such as polyester, vinyl ester, epoxy and phenolic resins.

Woven Roving are high-performance reinforcement widely used in hand lay-up and robot processes for the production of boats, vessels, plane and automotive parts, Pipe, furniture and sports facilities.

Spray-up Roving is an E-glass roving designed for spray-up process. It is treated with a silane-based size and compatible with unsaturated polyester resin and vinyl ester resins. Unique sizing technology imparts excellent spray-up properties to the product. Correct application will result in a reduced operating time. Tests have proved that the GRP end products have excellent water resistance. It is typically used to produce GRP boat hulls, sanitary apparatus, pipes, automotive parts cooling towers.

Direct Roving is an E-glass roving produced by directly winding a certain number of individual fibers from the bushing without twist. It is coated with a silane-based size and is designed for reinforcing unsaturated polyester, epoxy, vinylester and phenolic resins. It is specially used to produce GRP FRP pipes ,pressure vessels, gratings and profiles and, when converted into woven rovings, boats and chemical storage tanks. with filament winding, pultrusion and weaving process.

SMC Roving is an E-glass roving designed for SMC where filling agent and dying agent are added. It offers superior runability and less surface shrinkage and excellent mechanical properties of the GRP end products. SMC Roving is treated with a high performance silane-based size and is compatible with polyester resin and vinyl ester resins. It is a structural SMC roving and can also be used for surface grade SMC after an appropriate adjustment of SMC recipe. It is typically used to produce automotive parts, doors, chair, bathtubs, and water tanks and sports apparatus.

Panel Roving is an E-glass roving designed for continuous panel moulding process. It is treated with a silane-based size and compatible with unsaturated polyester, polyurethane resin and vinyl ester resins.

Panel Roving is typically used to produce various GRP/FRP Panels which offer light weight, high strength, high impact resistance and good light transmittance.

Fiberglass Yarn is a kind of twisting folded yarn wound by both C and E-Glass textile. Which has the characteristics of high strength, corrosion resistance, heat resistance and great moistureproofing. E-Glass Yarn has good electric insulation feature. It is used for wire wrapping, protection sleeve, fuse and insulation material in motor. It is also the primary material of woven roving and other industrial yarn. We can supply the yarn wound onto either big or small paper tube in different roll weight.

Surface Tissue mainly used in the surface layers of FRP Products. It is featured as uniform fiber distribution, soft touching, smooth surface, less glue content, quick resin soak and good pattern fitness. It can improve the product surface property on corrosion resistance, pressure resistance, leakproof performance and longer serving life. it is also suitable for spraying, pattern pressing and other FRP pattern technologies.

Fiberglass Mesh is produced by fiberglass fabrics with special surface treatments, It is kind of necessary structure material in the EIFS(Exterior Insulation and Finish System). The fiberglass mesh has high strength, good cohesion characteristics and can combine with EPS board firmly. Moreover, it can resist corrosion from building material such as cement and other alkaline materials, also prevent wall's cracking, improve wall's stress and impact resistance. Therefore, it is an ideal reinforcement material.

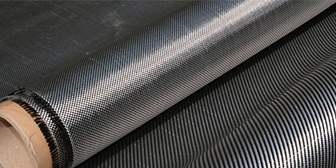

Compared to the traditional materials such as steel, Carbon fiber is currently most popular reinforcement material with features of light weight, high tensile strength, good corrosion resistance and climate adaptability. Moreover it can be used in high temperature environment because of its good thermal conductivity and heat resistance. Nowadays the carbon fiber is widely used in the field of energy, automobiles, trains, ships, civil aviation, construction, medical, equipment manufacturing, sports, and recreation. Our company can provide you 1K, 3K, 6K, 12K and other different specifications carbon fabrics.

Chopped Strands are coated with a silane-based coupling agent system and are compatible with different resin systems such as PA, PP, PET, PBT, PC, AS, ABS, UP and phenolic resins.

Chopped Strands are designed as reinforcement for thermoplastic and thermoset resins and are used in thermoplastic plastic and BMC/DMC. The main molding processes are injection and compression. The product is mainly used in the automobile industry, home appliances, valves, pump housings, chemical corrosion control and sports equipment.

Stitched Combo Mat is compatible with polyester, vinyl ester, phenolic and epoxy resins. The product is widely used in pultrusion, hand lay-up and RTM processes. The product is used most widely in the boat industry and typical end-use applications include FRP boat hulls, automotive housings and doors, laminates, cooling apparatus and structural shapes. Stitched Combo Mat is a complex mat made by stitching together a layer of rovings consisting of parallel aligned rovings (0 °, 90 ° )or (±45) and a layer of evenly distributed chopped strands.

Steel Wire-Fiberglass Blended Fbric is manufactured by stainless steel wire and fiberglass yarn. It can increase strength when encounter the high temperature. Widely used in steel, power, metallurgy, chemical industry, environmental protection, cement and other industries, widely used in the exhaust, ventilation, ventilation and dust, exhaust system to handle the role of pipeline compensation etc. Becuase of the fine wire thermal conduction properties of Steel-Fiberglass cloth ability instantaneous heat, also for brake friction materials.

Fiberglass cloth is an engineering material, which has the excellent merit such as anti-burns, anti-corrosion, stable-size, heat-isolation, minimum elongated shrinkage, high intensity, this new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc.